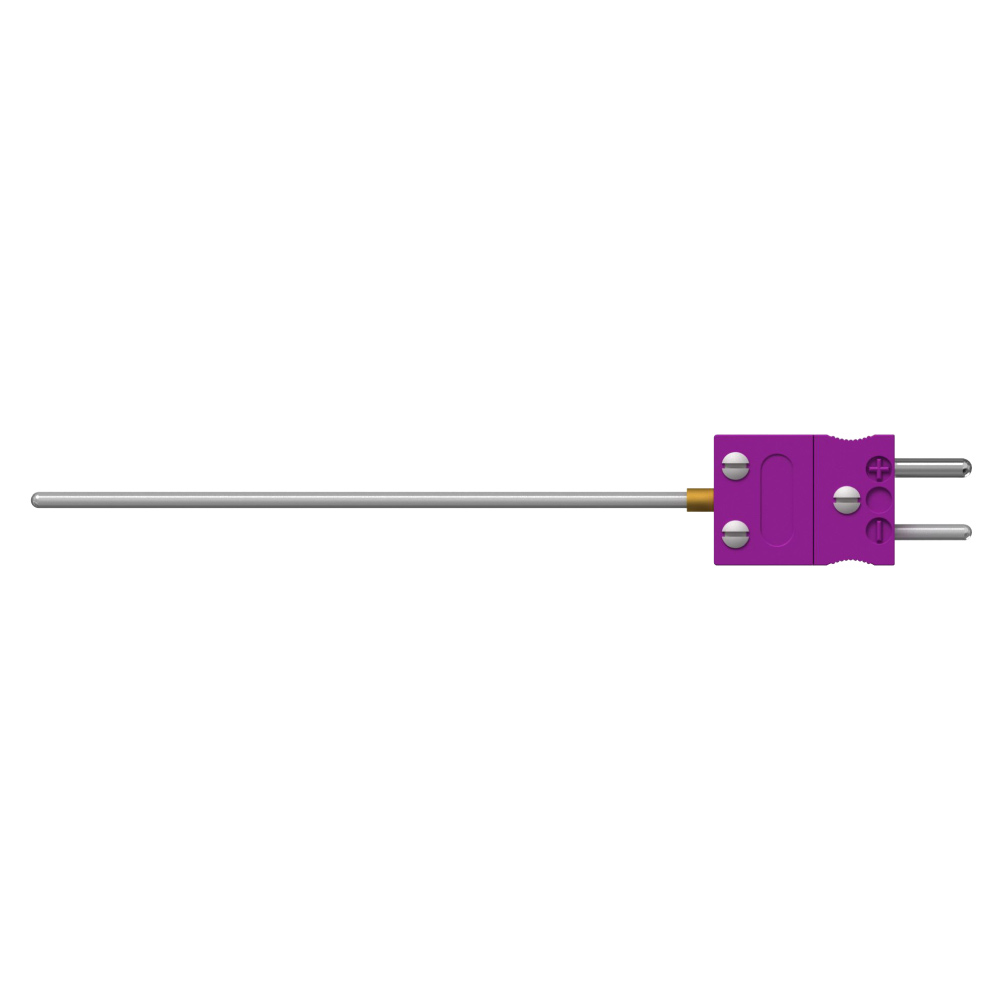

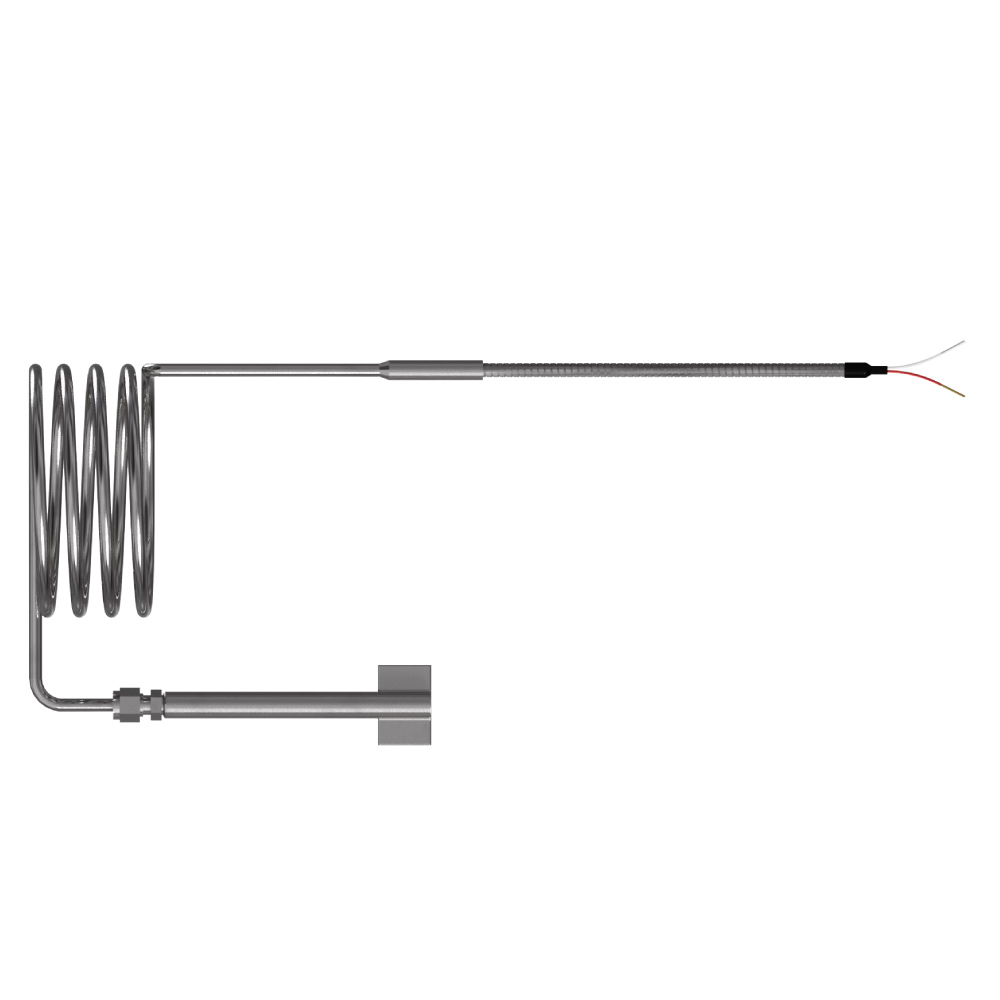

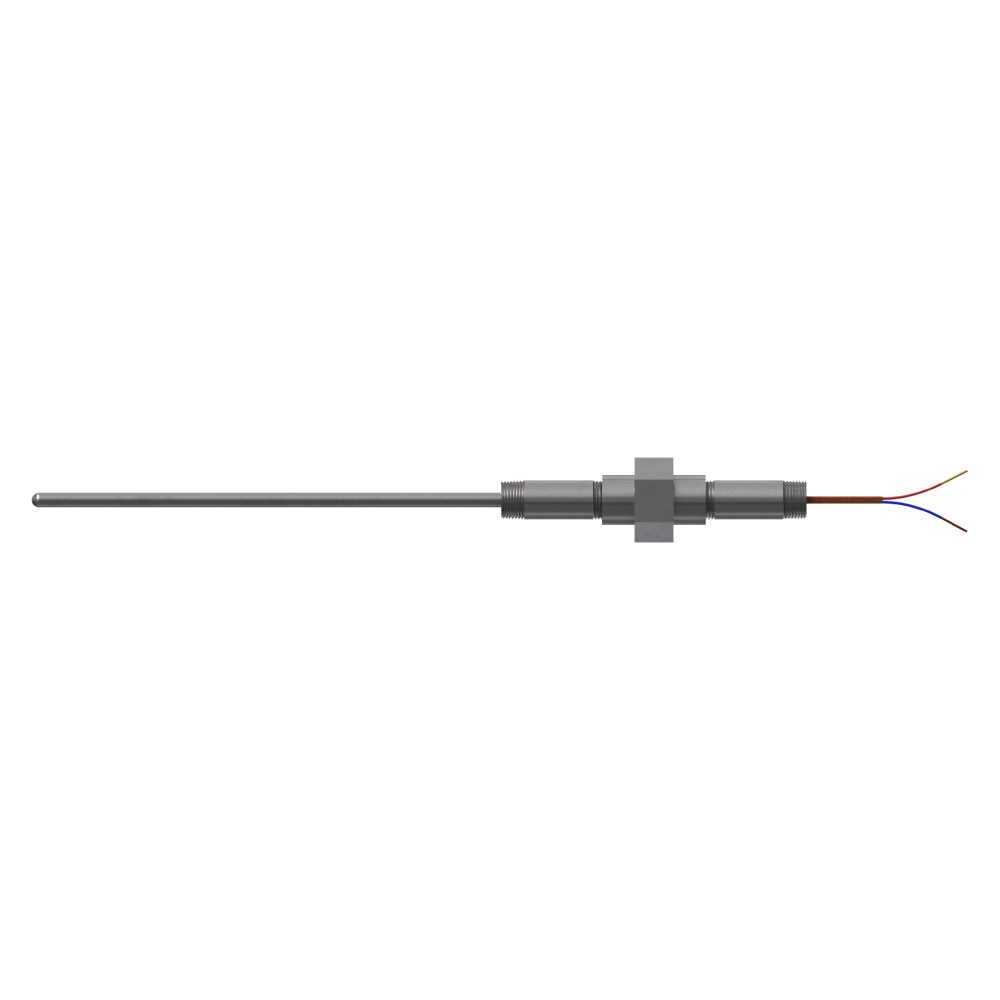

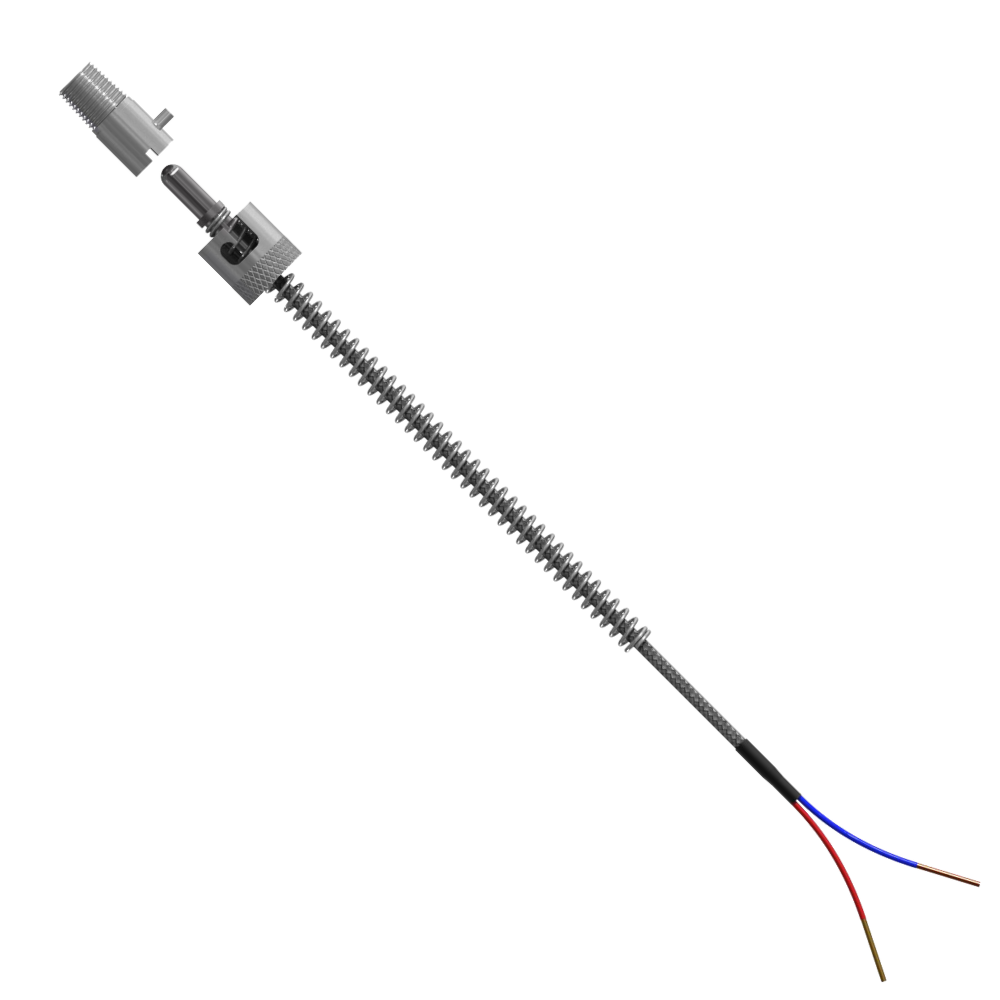

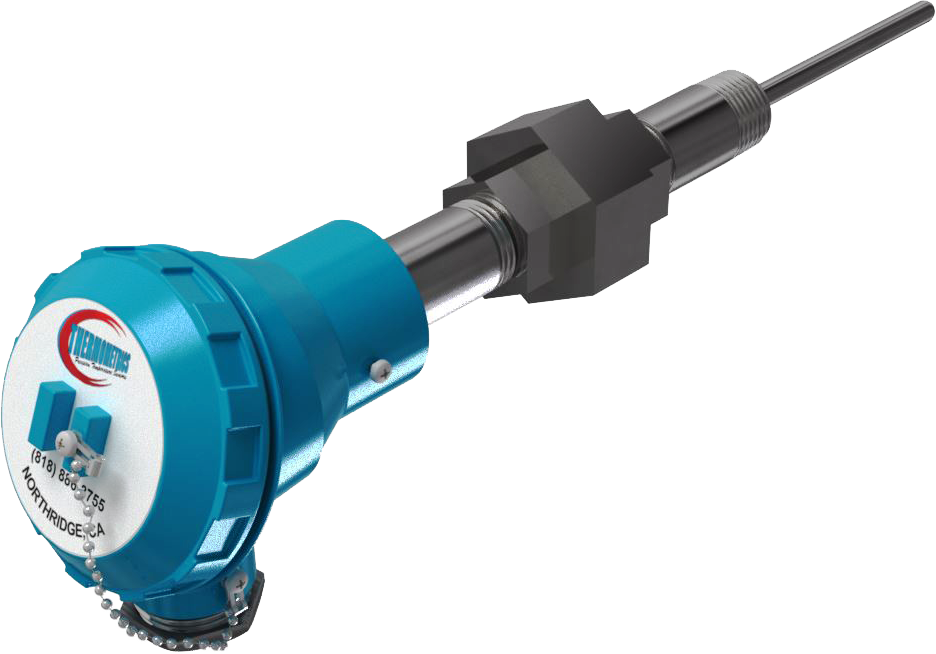

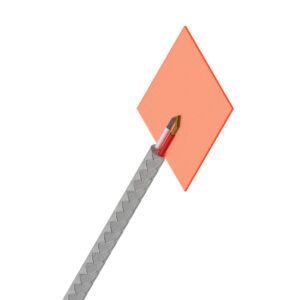

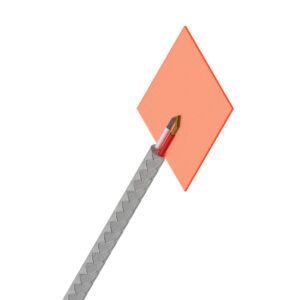

Stick On Surface Thermocouple

Thermocouples offer versatile, high-temperature measurement with rapid response times and rugged durability, making them ideal for industrial, automotive, aerospace, and process control applications.

Stick On Surface Thermocouple

A versatile, high-temperature thermocouple designed for adjustable placement in industrial, HVAC, and automotive applications with fast response time and durable sheathing.

Adjustable Thermocouple Insights

✅ Overall Score

Accuracy

Response Time

Temperature Range

Stability Over Time

Environmental Durability

Vibration Resistance

Chemical Resistance

Long-Distance Signal Accuracy

Compatibility with Data Systems

Contact vs. Non-Contact Measurement

Energy Efficiency / Power Needs

Cost-Effectiveness

Suitability for Extreme Cold

Suitability for Extreme Heat

Food & Medical Compliance

Overheat Protection & Safety

Automotive & Engine Performance

Industrial Process Control Suitability

HVAC & Climate Control

Ease of Installation & Maintenance

Temperature Sensor Overview:

Thermocouples are among the most widely used temperature sensors, capable of measuring extreme heat up to 1800°C. Designed for industrial, automotive, aerospace, and laboratory applications, these sensors deliver fast response times, durability, and self-powered operation. Thermocouples are available in various types (J, K, T, E, N, R, S, B), each optimized for different environments and accuracy needs. With options like mineral-insulated cables, stainless steel sheathing, and high-temperature ceramic coatings, thermocouples ensure long-lasting performance even in harsh conditions.

Temperature Sensor Specifications:

- Temperature Sensor Type: Thermocouple (J, K, T, E, N, R, S, B)

- Material Type: Stainless Steel, Ceramic, Inconel, Mineral-Insulated

- Accuracy: ±0.5°C to ±2.0°C (varies by type and application)

- Industries: Industrial Process Control, Aerospace, Automotive, Power Generation, Food Processing, Medical, HVAC

Accuracy Levels

Temperature Range

Handles extreme temperatures up to 1800°C, ideal for high-heat environments.

Response Time

Fast-reacting bead-type thermocouples vs. metal-sheathed probes with slower but stable readings.

Contact vs. Non-Contact Sensors

Requires direct contact for accuracy; infrared sensors are used for remote measurement.

Signal Stability

Thermocouples require cold-junction compensation to correct for voltage fluctuations.

Power Requirements

Self-powered, no external power needed, unlike RTDs and thermistors.

Environmental Durability

Available in stainless steel, ceramic, or mineral-insulated versions for harsh conditions.

Calibration & Maintenance

Regular calibration is required for precision in industrial and scientific applications.

Insulation & Sheathing

Mineral-insulated thermocouples reduce electrical interference and extend sensor life.

Sensor Placement & Installation

Proper mounting and airflow exposure prevent inaccurate readings.

Wire Length & Resistance Errors

Long cable runs can affect accuracy; 4-wire RTDs compensate for resistance errors.

Overheat Protection

PTC thermistors automatically increase resistance to prevent overheating.

Waterproof & Humidity Resistance

Sealed thermocouples for marine, refrigeration, and high-humidity applications.

Wireless & IoT Integration

Bluetooth, Wi-Fi, and Zigbee-enabled thermocouples for real-time remote monitoring.

Industry-Specific Sensors

Primarily urban, with some applications in off-grid living

Food & Medical Safety Compliance

FDA-approved stainless steel thermocouples for food and healthcare monitoring.

Extreme Cold Performance

Type T thermocouples & cryogenic RTDs for sub-zero applications.

Automotive & Transportation Sensors

Engine coolant, oil, exhaust, and battery monitoring for optimized vehicle performance.

Industrial Process Control

Essential for chemical plants, power generation, and manufacturing safety.

Protective Enclosures for Longevity

Ceramic sheaths, stainless steel enclosures, explosion-proof junction boxes extend lifespan.

Accuracy of Thermocouples

Thermocouples offer reliable and widely used temperature measurement, but their accuracy depends on thermocouple type, environmental conditions, and proper calibration. While they are highly versatile, thermocouples generally have a wider margin of error compared to RTDs and thermistors, with accuracy typically ranging from ±0.5°C to ±2.0°C.

Key Factors Affecting Accuracy:

- Thermocouple Type: Different thermocouple types (J, K, T, E, N, R, S, B) have varying accuracy levels. Platinum-based thermocouples (Type R, S, B) provide higher precision, while base-metal thermocouples (Type J, K, T) may have greater variation.

- Cold-Junction Compensation: Unlike RTDs, thermocouples measure temperature based on voltage differences, meaning they require cold-junction compensation to adjust for ambient conditions. Without proper compensation, readings can be off by several degrees.

- Signal Interference & Wiring: Long wire runs and electromagnetic interference can impact accuracy. Mineral-insulated thermocouples and shielded cables help maintain precision over long distances.

- Drift & Calibration: Over time, exposure to high temperatures, oxidation, and contamination can cause drift, requiring periodic recalibration to maintain reliable readings.

Despite these factors, thermocouples remain the preferred choice for high-temperature, industrial, and fast-response applications, where extreme conditions outweigh the need for ultra-precise measurements. When properly installed and maintained, they deliver accurate and dependable performance across a wide range of environments.

Response Time of Thermocouples

Thermocouples are known for their fast response times, making them ideal for applications where rapid temperature changes need to be detected. Their speed depends on factors such as sensor type, junction style, and protective sheathing.

Key Factors Affecting Response Time:

-

Junction Type:

- Exposed Junction Thermocouples – The fastest response, as the sensing element is directly exposed to the environment. Ideal for air, gas, and liquid temperature monitoring, but less durable.

- Grounded Junction Thermocouples – Faster than ungrounded, as the sensing element is in direct contact with the sheath, offering a good balance between speed and durability.

- Ungrounded Junction Thermocouples – The slowest but provides electrical isolation, reducing interference in industrial settings.

-

Sensor Sheathing:

- Bead-Type Thermocouples (without insulation) react almost instantly to temperature changes.

- Mineral-Insulated (MI) Thermocouples offer good response time while protecting the sensor in harsh conditions.

- Heavy-Duty Metal Sheaths (stainless steel, ceramic) provide protection but slow response time due to heat transfer delay.

-

Application Medium:

- Direct contact with liquids, gases, or metals results in faster readings than measuring air temperature, where thermal lag is greater.

- Thin, small-diameter thermocouples react more quickly than larger, thicker probes.

Why Thermocouples Are Preferred for Fast Response Applications:

✔ Ideal for dynamic processes requiring real-time temperature adjustments.

✔ Suitable for high-speed industrial applications, including engine monitoring, manufacturing, and medical devices.

✔ Faster than RTDs and thermistors in many cases, particularly in exposed and grounded junction designs.

When speed is a priority, exposed or grounded junction thermocouples with minimal sheathing provide the fastest and most accurate response times.

Temperature Limits of Thermocouples

Thermocouples are designed to operate across an exceptionally wide temperature range, making them ideal for applications requiring high-temperature resistance or extreme cold tolerance. Different thermocouple types have varying temperature limits, with some capable of measuring up to 1800°C (3272°F) or as low as -270°C (-454°F) in cryogenic environments.

Key Factors Affecting Temperature Limits:

-

Thermocouple Type:

- High-Temperature Performance:

- Type B, R, S – Can withstand temperatures up to 1800°C (3272°F), making them ideal for furnaces, molten metal, and aerospace applications.

- Type K, N – Common for industrial use, handling up to 1260°C (2300°F) while maintaining good accuracy.

- Low-Temperature Performance:

- Type T, E – Suitable for cryogenic applications, measuring as low as -270°C (-454°F).

- Type J – Used in moderate-temperature applications, but with a lower limit than Type K.

- High-Temperature Performance:

-

Material & Sheathing:

- Bare-Wire Thermocouples – Offer high-temperature sensitivity but degrade faster in extreme conditions.

- Mineral-Insulated Thermocouples (MI) – Extend lifespan and improve durability at high temperatures.

- Ceramic-Sheathed Thermocouples – Provide excellent high-temperature resistance, but are brittle.

-

Oxidation & Environmental Factors:

- Type K and N thermocouples resist oxidation, making them more durable at high temperatures.

- Type B, R, and S are platinum-based, offering superior stability in extreme heat but are more expensive.

Why Thermocouples Are the Preferred Choice for Extreme Temperatures:

✔ Handle the highest temperatures of any common temperature sensor, outperforming RTDs and thermistors.

✔ Can measure extreme cold, making them ideal for cryogenic and aerospace applications.

✔ Different types are optimized for specific environments, from industrial furnaces to engine exhaust systems.

By selecting the right thermocouple type and sheath material, these sensors can deliver precise and reliable readings in even the most challenging thermal environments.

Contact vs. Non-Contact Thermocouples

Thermocouples are primarily contact-based temperature sensors, meaning they must physically touch the surface or medium they are measuring. Unlike infrared (IR) and thermal imaging sensors, which measure temperature remotely, thermocouples rely on direct heat transfer for accurate readings.

Contact Thermocouples (Direct Measurement)

✔ How They Work: Measure temperature by touching a surface, liquid, or gas and generating a voltage based on the heat difference between two metals.

✔ Best For: Industrial equipment, metal surfaces, pipes, furnaces, engines, and food processing.

✔ Advantages:

- Higher accuracy in stable environments compared to non-contact methods.

- Can be embedded into machines, engines, and industrial processes for continuous monitoring.

- Available in grounded, ungrounded, and exposed junction configurations to balance speed and durability.

✔ Limitations: - Requires physical contact, which may slow response time in insulated or large surfaces.

- Not ideal for moving objects, hazardous environments, or high-voltage applications where contact is unsafe.

Non-Contact Temperature Measurement (Infrared vs. Thermocouples)

✔ Infrared (IR) Sensors & Thermal Cameras: Use radiation-based heat detection to measure temperature remotely, with no direct contact.

✔ Best For: Measuring hot, moving, or inaccessible surfaces, such as rolling steel, engines, or electrical components.

✔ Advantages of Non-Contact Sensors Over Thermocouples:

- Safer for extreme heat applications (e.g., molten metals, high-voltage systems).

- Can measure moving objects instantly with no physical attachment.

✔ Limitations: - Less precise than thermocouples in controlled environments.

- Affected by emissivity, reflections, and environmental interference like dust or smoke.

Which Should You Choose?

- Use Thermocouples when direct contact is possible, high accuracy is required, and long-term monitoring is needed.

- Use Infrared Sensors when measuring moving parts, inaccessible areas, or extremely high temperatures where contact is unsafe.

While infrared sensors provide convenience, thermocouples remain the industry standard for precision, durability, and cost-effectiveness in contact-based temperature measurement.

Durability of Thermocouples

Thermocouples are built for rugged environments, offering high durability in extreme temperatures, harsh chemicals, mechanical stress, and vibration-heavy applications. Their durability depends on sensor type, sheath material, insulation, and environmental conditions.

Key Factors Affecting Thermocouple Durability:

✔ Sheath Material & Protection

- Stainless Steel – Highly resistant to corrosion, moisture, and mechanical wear, commonly used in industrial settings.

- Inconel & Nickel Alloys – Withstands oxidation and high temperatures (up to 1200°C+), ideal for furnaces and aerospace applications.

- Ceramic Sheathing – Provides maximum heat resistance for extreme high-temperature applications (up to 1800°C) but is brittle.

✔ Mineral Insulated (MI) Thermocouples

- Superior durability due to a high-density insulation layer, preventing moisture ingress and mechanical damage.

- Highly flexible while maintaining protection against environmental hazards.

✔ Vibration & Mechanical Resistance

- Mineral-insulated and armored thermocouples withstand high-vibration environments such as automotive, aerospace, and heavy machinery.

- Bead-type thermocouples are more fragile and prone to breakage in high-impact conditions.

✔ Chemical & Moisture Resistance

- Teflon-coated and glass-insulated thermocouples resist acids, oils, and moisture, making them ideal for chemical processing and marine environments.

- Bare-wire thermocouples degrade quickly in harsh environments without proper shielding.

✔ Oxidation & Wear Protection

- Type K and Type N thermocouples are designed to resist oxidation at high temperatures, extending lifespan in industrial furnaces.

- Platinum-based thermocouples (Type R, S, B) offer excellent long-term stability and oxidation resistance.

How Thermocouples Compare to Other Sensors in Durability

✅ More durable than RTDs and thermistors in high-heat industrial settings.

✅ Withstand extreme conditions where other sensors fail, including high-vibration and chemically aggressive environments.

✅ Flexible options (MI cables, armored sheaths) allow for extended durability in harsh conditions.

By selecting the right sheath, insulation, and junction type, thermocouples can provide long-lasting, highly durable temperature monitoring, even in the most demanding environments.

Long-Term Accuracy of Thermocouples

Thermocouples provide reliable temperature measurements, but their long-term accuracy can drift over time due to environmental exposure, material degradation, and operational factors. While thermocouples are ideal for high-temperature and industrial applications, they require regular calibration to maintain accuracy over extended use.

Key Factors Affecting Long-Term Accuracy:

✔ Drift Over Time

- Thermocouples experience drift due to oxidation, contamination, and mechanical stress.

- Base-metal thermocouples (Type J, K, T, E, N) can drift by several degrees over time, especially in high-heat environments.

- Platinum thermocouples (Type R, S, B) offer better long-term stability, making them ideal for precise industrial applications.

✔ High-Temperature Exposure & Oxidation

- Continuous operation at elevated temperatures can cause thermocouple wires to oxidize and degrade, leading to accuracy loss.

- Type N thermocouples resist oxidation better than Type K, improving long-term performance.

- Protective sheathing (Inconel, stainless steel, or ceramic) can slow degradation and extend accuracy lifespan.

✔ Cold-Junction Compensation (CJC) Stability

- Thermocouples require cold-junction compensation (CJC) to adjust for ambient temperature changes.

- Inconsistent compensation electronics or fluctuations in reference temperature can introduce errors.

✔ Regular Calibration for Long-Term Precision

- Annual calibration is recommended for thermocouples used in precision applications.

- Industrial process control and laboratory settings may require frequent recalibration to maintain measurement accuracy.

- Digital signal conditioning can help reduce drift-related inaccuracies over time.

How Thermocouples Compare to Other Sensors in Long-Term Accuracy

🔸 RTDs offer better long-term accuracy due to stable resistance changes over time.

🔸 Thermistors provide highly precise readings initially, but can degrade faster than RTDs or thermocouples.

✅ Thermocouples remain the best choice for high-temperature and rugged industrial applications, despite potential drift.

While thermocouples require periodic calibration, choosing the right thermocouple type, protective sheathing, and installation method can significantly improve long-term accuracy and stability.

Key Industries Where Thermocouples Excel:

✔ Industrial Process Control & Manufacturing

- Used in chemical plants, power generation, metallurgy, and refining to monitor extreme temperatures.

- Type K and N thermocouples provide reliable readings in high-heat industrial furnaces and kilns.

- Platinum-based thermocouples (Type R, S, B) are preferred for precise high-temperature control.

✔ Aerospace & Defense

- Essential for jet engine monitoring, exhaust gas temperature (EGT) sensing, and spacecraft thermal management.

- Mineral-insulated thermocouples withstand high-vibration and extreme thermal conditions.

- Type C and Type B thermocouples are commonly used in rocket and propulsion systems.

✔ Automotive & Transportation

- Used for engine coolant, exhaust gas, catalytic converter, and battery temperature monitoring.

- Fast-response thermocouples help optimize fuel efficiency and emissions control.

- High-temperature thermocouples (Type K) are used in turbochargers and combustion testing.

✔ Food & Beverage Processing

- FDA-approved stainless steel thermocouples are used in meat processing, brewing, dairy, and HACCP-compliant monitoring.

- Type T and J thermocouples offer accurate readings in food storage, pasteurization, and cooking applications.

- Used in ovens, fryers, and industrial sterilization processes to ensure safety and compliance.

✔ Medical & Pharmaceutical

- Used in lab freezers, autoclaves, sterilization, and medical device temperature monitoring.

- Type T thermocouples provide precision in cryogenic storage and vaccine preservation.

- Platinum thermocouples are used in clinical and research applications for long-term stability.

✔ HVAC & Environmental Monitoring

- Used in boilers, heat exchangers, and air handling systems for temperature regulation.

- Type J and K thermocouples are standard in climate control and ventilation systems.

- Helps maintain energy efficiency and air quality monitoring.

✔ Energy & Renewable Resources

- Essential in geothermal, solar, and nuclear power plants to measure heat transfer and efficiency.

- Used in wind turbines and hydroelectric stations to monitor operational temperatures.

- High-temperature ceramic-sheathed thermocouples withstand extreme conditions in energy production.

Why Thermocouples Are the Industry Standard:

✅ Versatile across multiple industries due to high-temperature capability and durability.

✅ Cost-effective and widely available, making them ideal for large-scale applications.

✅ Fast response time for real-time monitoring, essential in automotive, aerospace, and manufacturing.

✅ Highly customizable, with different types, sheath materials, and installation options to fit specific industry needs.

By selecting the right thermocouple type and configuration, industries can achieve precise, reliable, and efficient temperature monitoring in even the most challenging environments.

Smart & Wireless Thermocouples: Modern Temperature Monitoring Solutions

The evolution of smart and wireless thermocouples has revolutionized temperature monitoring by offering real-time data transmission, remote access, and IoT integration. These advanced thermocouples eliminate the need for traditional wired setups, reducing installation complexity and maintenance costs while improving data accuracy and accessibility.

Key Features of Smart & Wireless Thermocouples:

✔ Bluetooth & Wi-Fi Connectivity

- Wireless thermocouples use Bluetooth, Wi-Fi, or LoRaWAN to transmit real-time temperature data to mobile apps, cloud dashboards, and industrial systems.

- Ideal for remote monitoring in factories, laboratories, and field applications.

✔ IoT & Cloud Integration

- Can be integrated with SCADA, PLCs, and industrial IoT (IIoT) platforms for real-time temperature tracking.

- Smart alerts and automation trigger maintenance actions when temperature thresholds are exceeded.

- Data logging capabilities allow for long-term trend analysis and predictive maintenance.

✔ Battery-Powered & Energy-Efficient Designs

- Many smart thermocouples are battery-operated or use energy-harvesting technologies, eliminating the need for wired power sources.

- Long battery life enables continuous operation in remote locations.

✔ Industrial-Grade Wireless Reliability

- Uses encrypted transmission protocols to ensure secure and interference-free data communication.

- Available in rugged, high-temperature enclosures for harsh environments.

✔ Mobile & Web-Based Monitoring

- Temperature data can be viewed in real-time via mobile apps, web dashboards, or industrial control panels.

- Cloud-based monitoring allows global access to temperature readings, improving operational efficiency.

Applications of Smart & Wireless Thermocouples:

🔹 Manufacturing & Industrial Process Control – Enables real-time tracking of production temperatures, reducing downtime.

🔹 Automotive & Aerospace – Wireless exhaust gas and engine thermocouples improve testing efficiency.

🔹 Food & Beverage – Remote temperature monitoring for HACCP compliance in food processing.

🔹 Energy & Power Plants – IoT-enabled thermocouples optimize performance in solar, geothermal, and nuclear facilities.

🔹 Medical & Pharmaceutical – Smart sensors monitor cryogenic storage and sterilization processes.

Why Choose Smart & Wireless Thermocouples?

✅ Eliminates complex wiring for easier installation and flexibility.

✅ Real-time remote monitoring for improved efficiency and safety.

✅ IoT integration enables predictive maintenance, reducing equipment failures.

✅ Ideal for inaccessible or high-risk environments, such as power plants, aerospace, and hazardous areas.

With smart and wireless thermocouples, businesses can achieve better temperature control, improved safety, and lower maintenance costs, making them the future of modern temperature sensing technology.

Blog

Reviews of Adjustable Thermocouple

https://jvz4.com/c/688203/433889/

Most people don’t fail online because they lack opportunity.

They fail because the thinking overwhelms them.

What should I build?

How do I structure it?

What comes next?

That mental weight is what kills momentum.

ClawMate was built to remove that layer completely.

It’s not another chatbot waiting for prompts.

Click here for more : https://jvz4.com/c/688203/433889/

https://www.youtube.com/watch?v=ss4tux6Q4pI

Stop wasting months on content creation and start selling a professional, ready-to-use video course that positions you as an instant authority in the digital business space. This complete white-label package allows you to grow your email list and generate recurring income without spending a single minute on planning, scripting, or recording https://www.youtube.com/watch?v=ss4tux6Q4pI

https://www.youtube.com/watch?v=3013L2Yxg1k

Stop losing money on visitors who leave websites and start automatically redirecting that “wasted” traffic toward your own offers for as little as five cents per person. Exit Traffic Network provides a completely hands-free, set-it-and-forget-it system that captures real desktop traffic from established platforms while you sleep

https://www.youtube.com/watch?v=3013L2Yxg1k

https://www.youtube.com/shorts/A-OuNefvXeA

Discover how our AI can skyrocket your Temperaturesensors Us website leads in this quick video: https://www.youtube.com/shorts/A-OuNefvXeA

https://www.youtube.com/watch?v=ksq5cZApb3E

Skip months of hard work and launch a high-converting AI business today using this professionally designed “Business In A Box”. With full Private Label Rights, you can rebrand these expert assets as your own and keep 100% of the profits from every sale.