Contact Temperature Sensors

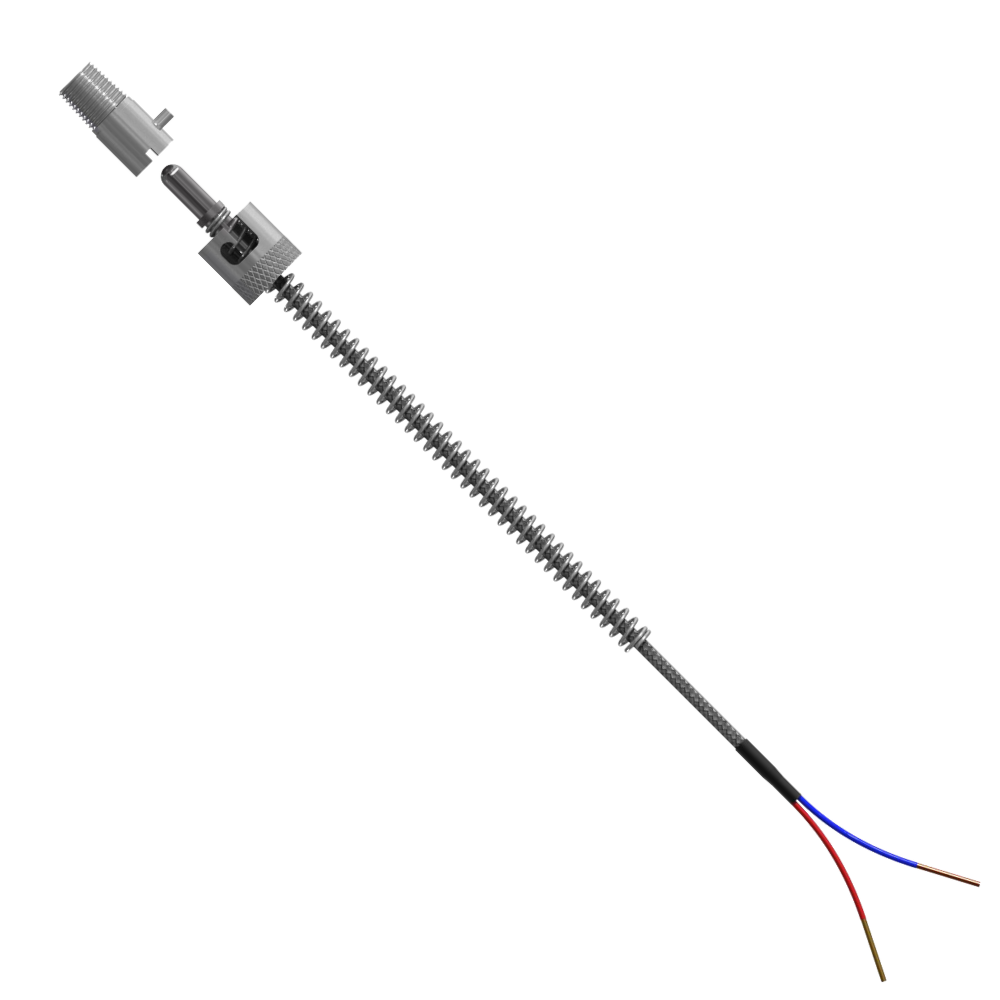

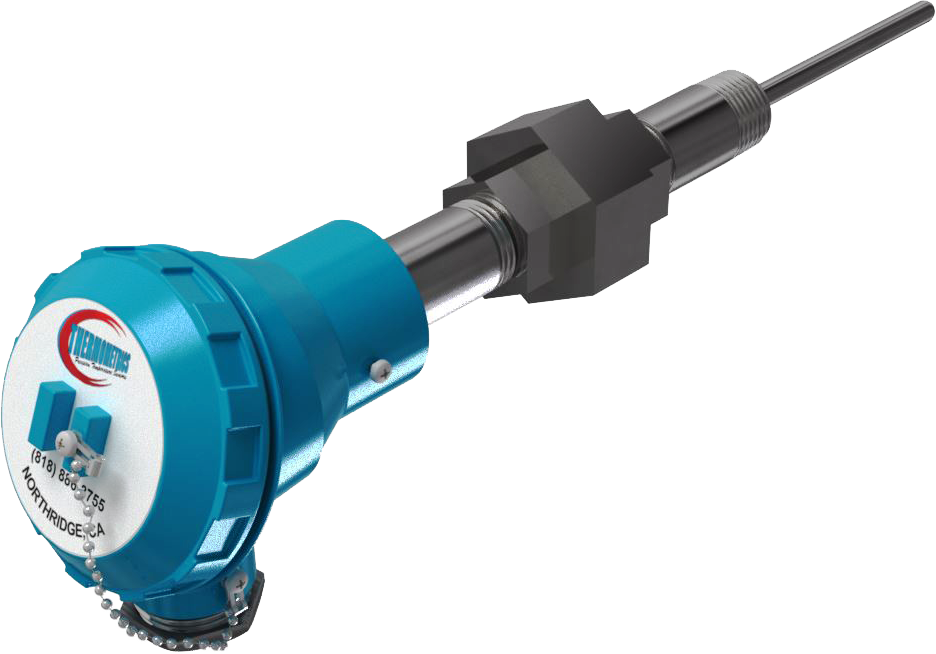

Reliable, high-performance contact temperature sensors designed for direct surface or embedded thermal monitoring across industrial and commercial systems.

Contact Temperature Sensors

Reliable, high-performance contact temperature sensors designed for direct surface or embedded thermal monitoring across industrial and commercial systems.

Contact Temperature Sensor Insights

✅ Overall Score

Accuracy

Response Time

Temperature Range

Stability Over Time

Environmental Durability

Vibration Resistance

Chemical Resistance

Long-Distance Signal Accuracy

Compatibility with Data Systems

Contact vs. Non-Contact Measurement

Energy Efficiency / Power Needs

Cost-Effectiveness

Suitability for Extreme Cold

Suitability for Extreme Heat

Food & Medical Compliance

Overheat Protection & Safety

Automotive & Engine Performance

Industrial Process Control Suitability

HVAC & Climate Control

Ease of Installation & Maintenance

Temperature Sensor Overview:

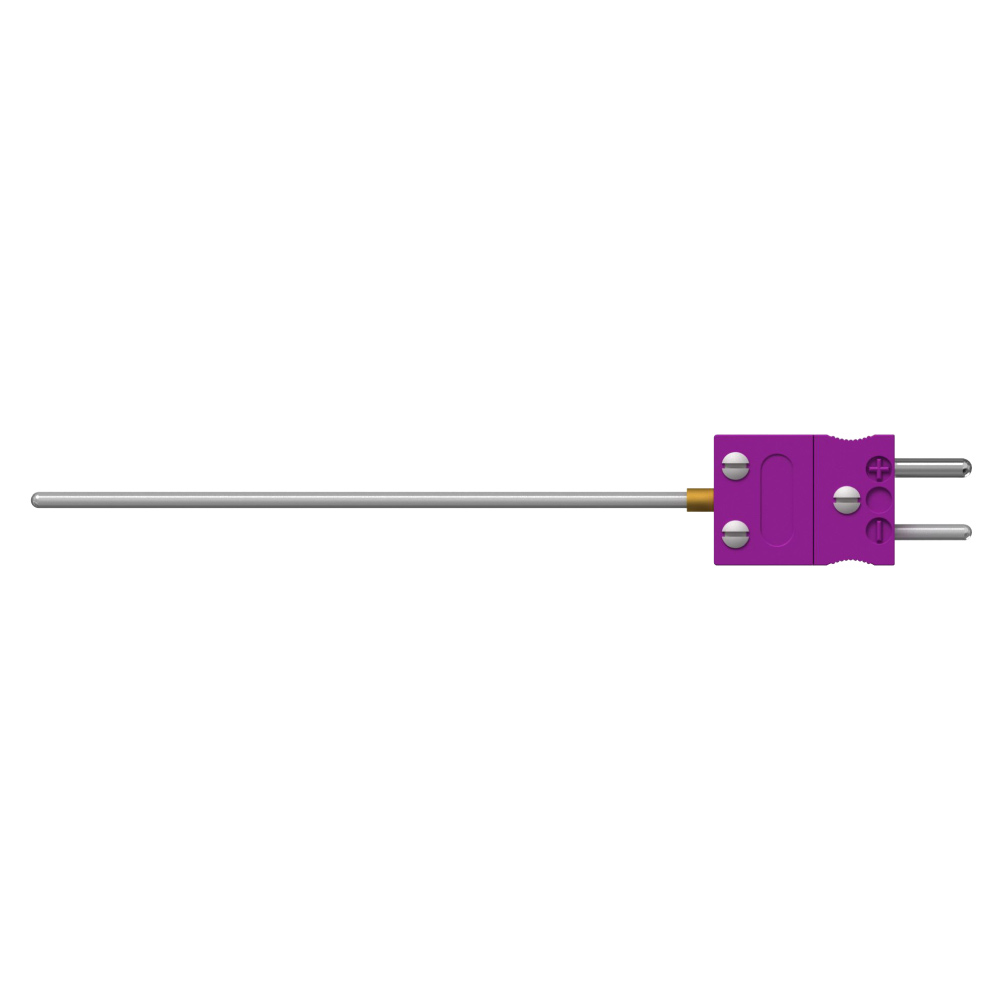

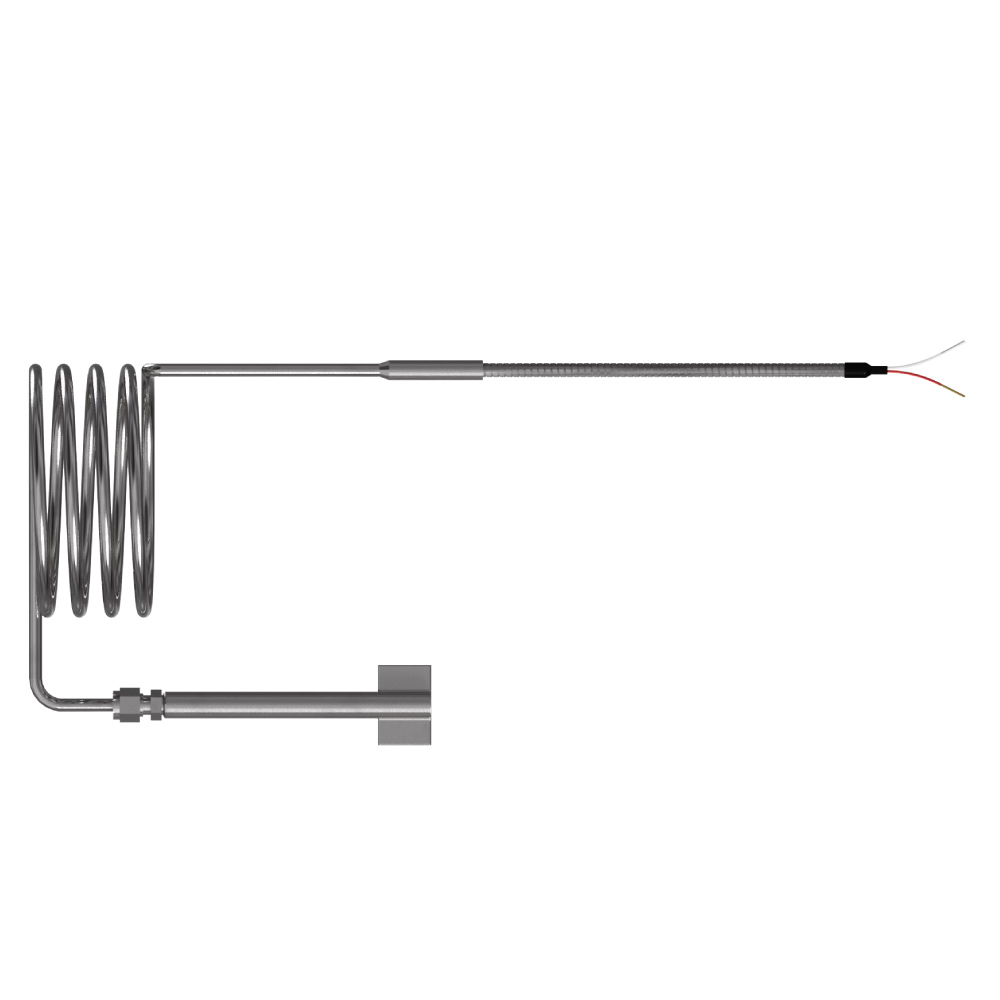

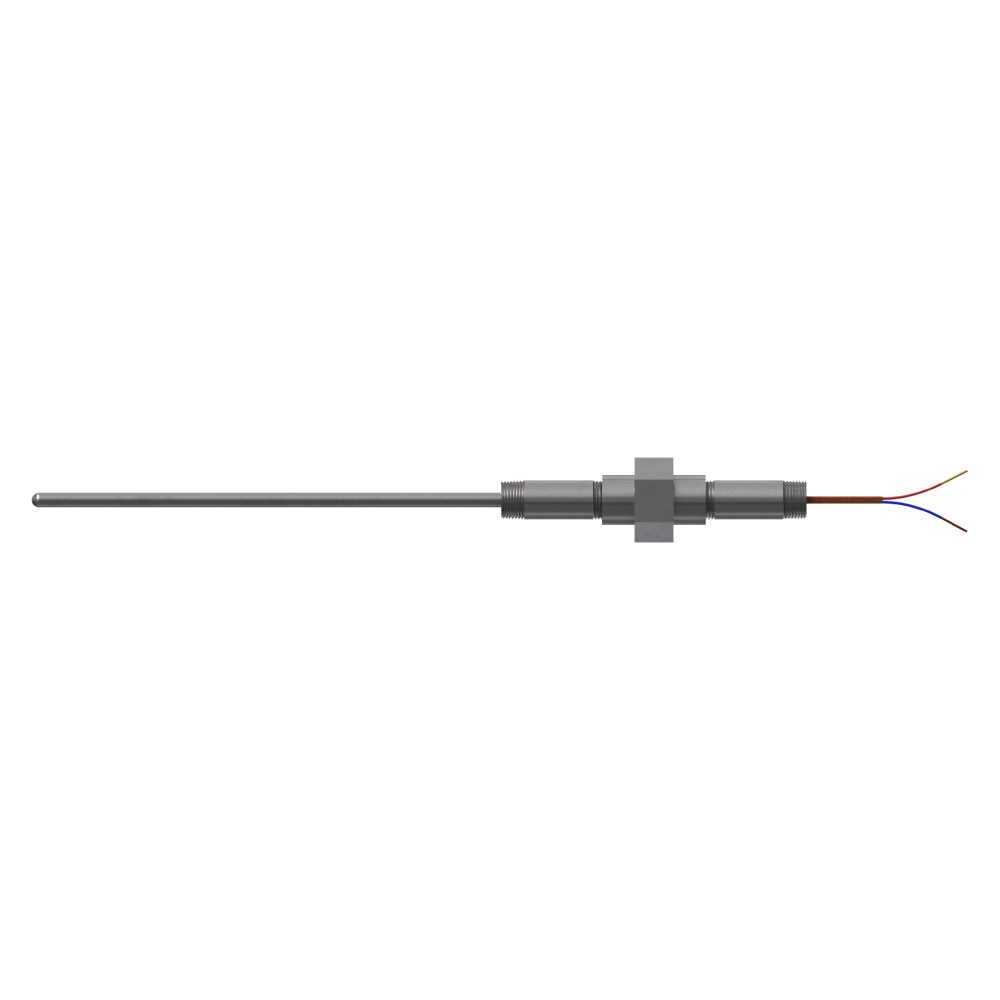

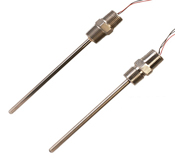

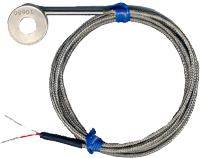

Our contact temperature sensors deliver dependable and accurate heat measurement for a wide range of applications. These sensors—available in RTD, thermocouple, and thermistor configurations—are designed for direct-contact installations on surfaces, inside equipment, or within fluid channels.

Each model is built with durable sheathing and optional waterproof sealing, making them suitable for environments involving vibration, moisture, or high pressure. Whether you’re monitoring equipment temperature, process heat, HVAC systems, or automotive components, contact sensors offer precise real-time data to support control systems, alarms, and predictive maintenance.

Available with 2-, 3-, or 4-wire outputs, analog or digital signal options, and multiple mounting types, these sensors integrate easily with both modern industrial platforms and legacy systems.

Temperature Sensor Specifications:

-

Temperature Sensor Type

-

RTD (PT100 / PT1000)

-

Thermocouple (Type K, J, T, E, N)

-

Thermistor (NTC / PTC)

Material Type

-

Stainless Steel

-

Ceramic

-

Epoxy-Sealed

-

Teflon/PTFE-Coated

Accuracy

-

RTDs: ±0.1°C to ±0.5°C

-

Thermistors: ±0.2°C to ±0.5°C

-

Thermocouples: ±0.5°C to ±2.0°C

Industries

✔ Food & Beverage

✔ Medical & Pharmaceutical

✔ HVAC

✔ Automotive & Transportation

✔ Manufacturing & Process Control

✔ Energy & Power Generation

✔ Aerospace & Defense

✔ Laboratory & Scientific Research -

Accuracy Levels

Temperature Range

Thermocouples can handle extreme temperatures, up to 1800°C, making them ideal for high-heat applications. RTDs and thermistors work best in the -50°C to 300°C range, offering better precision at lower temperatures.

Response Time

Bead thermistors and thin-film RTDs respond quickly (within 1–2 seconds). Probes with metal or ceramic sheathing may respond slower but provide better durability in tough conditions.

Contact vs. Non-Contact Sensors

Contact sensors require physical contact with the object or surface being measured, unlike infrared sensors, which detect surface heat remotely. Contact sensors provide more accurate and stable readings in most industrial settings.

Signal Stability

RTDs provide very stable resistance-based readings over time. Thermocouples can drift slightly due to environmental conditions and require cold-junction compensation for accurate readings.

Power Requirements

Thermocouples are self-powered, generating a small voltage. RTDs and thermistors need a stable power supply and external circuitry for signal conditioning.

Environmental Durability

Sensors built with stainless steel, ceramic, or Teflon-coated materials offer strong resistance to harsh environments including moisture, vibration, and mechanical stress.

Calibration & Maintenance

Contact sensors—especially those used in regulated environments—should be calibrated periodically to maintain accuracy. RTDs are favored where long-term precision is needed.

Insulation & Sheathing

Mineral-insulated thermocouples and shielded RTDs are used to prevent electromagnetic interference and physical wear, ensuring longevity in industrial systems.

Sensor Placement & Installation

Proper installation is critical. Placement too far from heat sources, poor contact, or incorrect mounting can cause thermal lag and inaccurate readings.

Wire Length & Resistance Errors

Long cable runs may impact accuracy, especially with thermistors or 2-wire RTDs. 4-wire RTDs are preferred for longer distances as they compensate for lead resistance.

Overheat Protection

PTC thermistors are used in some systems as over-temperature protection devices, increasing resistance sharply at high temperatures to reduce current and prevent damage.

Waterproof & Humidity Resistance

Contact sensors for marine, refrigeration, or outdoor environments are often glass-encapsulated or epoxy-sealed for resistance to moisture and humidity.

Wireless & IoT Integration

While traditional contact sensors are wired, many can now be connected to wireless transmitters (Bluetooth, Zigbee, Wi-Fi), enabling real-time data collection in remote or smart factory environments.

Industry-Specific Sensors

-

RTDs are standard in food processing, pharmaceuticals, and labs

-

Thermocouples are common in aerospace, metallurgy, and manufacturing

-

Thermistors are used in HVAC, appliances, and medical devices

Food & Medical Safety Compliance

Many contact sensors are available in sanitary-grade stainless steel and meet FDA, HACCP, or ISO 13485 requirements for use in food and healthcare systems.

Extreme Cold Performance

Cryogenic RTDs and Type T thermocouples offer accurate readings in sub-zero and cryogenic environments, such as cold storage, aerospace research, and medical freezers.

Automotive & Transportation Sensors

Contact sensors monitor engine coolant, battery temps, brake heat, and exhaust systems, supporting real-time diagnostics in vehicles and rail systems.

Industrial Process Control

In chemical plants, power stations, and refineries, contact sensors are tied directly into control systems for continuous monitoring and automated regulation.

Protective Enclosures for Longevity

Explosion-proof housings, armored cable, and high-IP enclosures ensure sensors last in tough conditions, reducing downtime and replacement frequency.

Accuracy – Contact Temperature Sensors

Accuracy is a critical factor in choosing a contact temperature sensor, especially in applications where precise thermal monitoring impacts product quality, safety, and system performance. Contact sensors—such as RTDs, thermocouples, and thermistors—are widely used for their ability to deliver accurate, real-time temperature readings through direct contact with a surface, fluid, or component.

The accuracy of a contact sensor depends on several factors, including the type of sensor element, the quality of construction, and the calibration method used. RTDs are generally the most accurate, followed by thermistors, with thermocouples offering a good balance of range and durability but slightly lower precision.

Typical Accuracy Ranges

-

RTDs: ±0.1°C to ±0.5°C – Ideal for scientific, medical, and food-grade applications

-

Thermistors: ±0.2°C to ±0.5°C – Great for HVAC, appliances, and temperature regulation

-

Thermocouples: ±0.5°C to ±2.0°C – Suitable for industrial and high-temperature applications

What Affects Accuracy

-

Sensor element type and material quality

-

Placement and mounting method (poor contact can reduce accuracy)

-

Cable length and resistance (especially in thermocouples and 2-wire RTDs)

-

Signal noise or interference (solved with shielding or digital signal conversion)

-

Environmental exposure and long-term drift

Why Accuracy Matters

-

Ensures safe and efficient equipment operation

-

Supports regulatory compliance in food, pharma, and lab settings

-

Allows for tight process control in manufacturing and automation

-

Enables early detection of anomalies in engines, systems, or machinery

Accuracy Score: 85 / 100

Contact temperature sensors earn an accuracy score of 85 out of 100, based on their high precision across multiple sensor types, particularly RTDs and thermistors. While thermocouples are slightly less accurate, they are still widely used where range and ruggedness are more important than extreme precision.

Response Time – Contact Temperature Sensors

Response time refers to how quickly a contact temperature sensor can detect and report a change in temperature after exposure to a new thermal condition. In many industrial and commercial applications, a fast response time is essential for maintaining safety, optimizing performance, and ensuring consistent product quality.

Contact sensors—such as RTDs, thermocouples, and thermistors—vary in their response speeds depending on their construction, tip design, insulation, and the material they’re measuring. Smaller sensors with exposed elements typically respond faster, while larger or heavily sheathed sensors may trade speed for durability.

Typical Response Times

-

Bead Thermistors: 0.5 to 2 seconds – Extremely fast, ideal for HVAC and appliances

-

Thin-Film RTDs: 1 to 5 seconds – Fast and stable, often used in precision systems

-

Thermocouples: 1 to 10 seconds – Depends on junction type (exposed, grounded, or ungrounded)

What Affects Response Time

-

Sensor tip size and shape

-

Material and thickness of sheathing

-

Contact pressure or thermal coupling to the measured surface

-

Environmental conditions (e.g., airflow, fluid movement)

-

Mounting method and installation location

Why Response Time Matters

-

Allows for quick system reaction to temperature changes

-

Enhances safety in overheating scenarios

-

Improves process efficiency and control

-

Supports dynamic environments like engines, HVAC systems, or automated lines

Application Suitability

-

Fast-response thermistors are excellent for HVAC and mobile systems

-

RTDs offer a great balance of speed and accuracy for industrial and lab use

-

Thermocouples provide durable, consistent performance with acceptable response time for higher temperature environments

Response Time Score: 85 / 100

Contact temperature sensors earn a response time score of 85 out of 100, offering quick, dependable performance in most applications. Whether you’re monitoring fluid lines, surface temperatures, or embedded components, contact sensors provide the speed and reliability needed for accurate, real-time thermal feedback.

Temperature Limits – Contact Temperature Sensors

Temperature limits define the minimum and maximum temperatures a contact sensor can accurately and safely measure. For systems that experience significant heat or operate in cold environments, choosing a sensor with the right temperature range is essential to ensure performance, safety, and sensor longevity.

Contact temperature sensors—such as RTDs, thermocouples, and thermistors—each offer different ranges depending on their internal element and housing materials. Thermocouples are best suited for extreme temperatures, while RTDs and thermistors provide better accuracy within more moderate ranges.

Typical Temperature Ranges

-

Thermocouples: -200°C to 1800°C (depending on type)

-

RTDs: -200°C to 850°C (ideal for industrial and lab use)

-

Thermistors: -50°C to 300°C (great for HVAC, appliances, and general use)

What Affects Temperature Limits

-

Sensor type and internal element (e.g., Type K thermocouple vs. PT100 RTD)

-

Sheathing material (stainless steel, ceramic, Teflon, etc.)

-

Mounting conditions and proximity to heat sources

-

Insulation, cable type, and exposure to environmental elements

Why Temperature Limits Matter

-

Ensures safe operation within known temperature extremes

-

Prevents sensor failure or drift caused by exceeding operating specs

-

Supports application-specific needs (e.g., high heat in furnaces or low temps in refrigeration)

-

Provides confidence in continuous performance in demanding environments

Application Suitability

-

Thermocouples are ideal for furnaces, engines, kilns, and aerospace

-

RTDs are widely used in manufacturing, labs, food processing, and energy

-

Thermistors are best for consumer electronics, HVAC systems, and temperature control applications

Temperature Range Score: 90 / 100

Contact temperature sensors earn a temperature range score of 90 out of 100 for their broad adaptability across environments. Whether used in ultra-cold freezers or extreme heat zones, there’s a contact sensor solution tailored to the thermal demands of the application.

Contact vs. Non-Contact – Contact Temperature Sensors

Contact temperature sensors are designed to measure temperature by making direct physical contact with the object, surface, or fluid they’re monitoring. This allows for highly accurate, stable, and reliable readings, especially in systems where consistent thermal feedback is essential for performance or safety.

Unlike non-contact sensors (such as infrared sensors), which measure surface temperature from a distance using emitted radiation, contact sensors capture the actual heat transfer through physical connection—making them ideal for closed systems, internal components, and controlled environments.

Key Differences

| Feature | Contact Sensors | Non-Contact Sensors |

|---|---|---|

| Measurement Method | Direct contact with surface/object | Senses emitted infrared radiation |

| Accuracy | High, especially for stable surfaces | Lower if surface is reflective or obstructed |

| Best For | Internal systems, fluids, metals | Moving parts, hazardous or hard-to-reach areas |

| Response Time | Fast, depending on sensor type | Instantaneous for exposed surfaces |

| Environmental Sensitivity | Less sensitive to dust/steam interference | Can be affected by dust, steam, glass |

| Installation | Requires mounting on/in equipment | No contact, can be handheld or mounted externally |

Why Contact Measurement Matters

-

Provides more accurate localized readings where thermal contact is needed

-

Essential for monitoring internal components, such as bearings, pipes, and housings

-

Ideal for environments where shielding or insulation prevents infrared sensing

-

Supports automation systems that require steady, reliable data input

Limitations of Non-Contact Sensors

-

Cannot measure through metal, glass, or protective enclosures

-

Accuracy may vary depending on surface material and environmental conditions

-

Less effective for fluids, embedded systems, or closed machinery

Application Suitability

-

Contact sensors are preferred in industrial process control, automotive systems, HVAC, food processing, and lab equipment

-

They offer a dependable choice for high-accuracy and long-term monitoring, especially where physical installation is possible

Contact vs. Non-Contact Score: 80 / 100

Contact temperature sensors score 80 out of 100 in this category. While they don’t offer the flexibility of non-contact sensors for remote or moving targets, they provide superior accuracy, reliability, and long-term performance in applications where precision is key.

Durability – Contact Temperature Sensors

Durability is a key advantage of contact temperature sensors, especially when used in demanding environments such as industrial facilities, automotive systems, and process equipment. These sensors are built to withstand mechanical stress, vibration, moisture, chemicals, and temperature extremes—ensuring long-term performance and minimal maintenance.

Most contact sensors feature robust designs with stainless steel, brass, ceramic, or Teflon sheathing, making them highly resistant to wear, corrosion, and impact. The internal components are often sealed or encapsulated to protect against dust, oil, humidity, and other environmental factors that could degrade performance.

Key Durability Features

-

High ingress protection (IP65 to IP67+) for moisture and dust resistance

-

Vibration-resistant construction for use in motors, pumps, and heavy machinery

-

Corrosion-resistant materials for exposure to harsh chemicals or cleaning agents

-

Armor-braided or insulated cables for protection in high-flex or high-heat areas

-

Long operational lifespan in 24/7 systems with minimal signal drift

Why Durability Matters

-

Reduces sensor failure and system downtime

-

Ensures accurate readings in harsh or unstable environments

-

Minimizes maintenance frequency and replacement costs

-

Supports critical equipment monitoring over extended use cycles

Application Suitability

-

Ideal for industrial automation, energy systems, food processing, transportation, and manufacturing

-

Performs well in environments with moisture, debris, vibration, and mechanical stress

Durability Score: 90 / 100

Contact temperature sensors score 90 out of 100 for durability, thanks to their rugged construction, sealed housings, and long service life. Whether installed in a production facility, vehicle, or lab, these sensors deliver consistent performance under pressure—literally and figuratively.

Long-Term Accuracy – Contact Temperature Sensors

Long-term accuracy refers to a sensor’s ability to consistently deliver precise temperature readings over extended periods of operation. For many systems—especially in industrial, scientific, and safety-critical environments—this consistency is just as important as initial precision. Contact temperature sensors are widely trusted for their excellent long-term stability, particularly when built with RTD elements.

Unlike some sensors that drift over time due to environmental exposure or internal degradation, well-designed contact sensors maintain their calibration for years when properly installed and used within specified temperature ranges. RTDs are particularly well-known for minimal drift, while thermocouples, though more rugged, may require periodic recalibration in high-temperature or fluctuating environments.

What Supports Long-Term Accuracy

-

High-quality sensing elements like platinum (used in RTDs)

-

Proper insulation and sheathing to protect against EMI, vibration, and heat

-

Stable materials and construction that resist aging and fatigue

-

Routine calibration protocols in regulated environments

-

Correct installation to avoid thermal lag or false readings

Why Long-Term Accuracy Matters

-

Ensures reliable temperature monitoring over months or years

-

Reduces the need for frequent recalibration or replacement

-

Supports compliance in industries like food, pharma, and medical manufacturing

-

Prevents drift-related issues in automated control systems and safety shutoffs

Application Suitability

-

Ideal for process control, lab monitoring, industrial machinery, and medical equipment

-

Frequently used in systems that run continuously or require minimal maintenance interruptions

Long-Term Accuracy Score: 85 / 100

Contact temperature sensors score 85 out of 100 for long-term accuracy. With high-quality materials, proper insulation, and correct installation, these sensors deliver reliable, low-drift performance even in long-duration or mission-critical applications.

Key Industries – Contact Temperature Sensors

Contact temperature sensors are essential across a wide range of industries where precise, reliable, and stable heat measurement is required. From monitoring equipment in industrial automation to ensuring compliance in food and pharmaceutical environments, these sensors offer the versatility and performance needed for both routine processes and critical operations.

Because they make direct contact with the surface or substance being measured, they are ideal for embedded, surface-mount, and fluid-based applications where accuracy, stability, and durability are top priorities.

Common Industries That Use Contact Temperature Sensors

1. Manufacturing & Industrial Automation

Used in motors, pumps, production lines, and processing equipment to monitor temperature changes that may indicate failure, wear, or inefficiency.

2. Food & Beverage Processing

RTDs and sanitary thermocouples are essential for ensuring safe cooking, chilling, pasteurization, and sterilization, all while meeting strict compliance standards.

3. HVAC & Building Systems

Thermistors and RTDs provide responsive and accurate temperature control in heating, ventilation, air conditioning, and refrigeration systems.

4. Medical & Pharmaceutical

Contact sensors are used in medical devices, lab environments, sterilization systems, and pharmaceutical manufacturing, where accuracy and compliance are critical.

5. Automotive & Transportation

Contact sensors monitor engine temperature, exhaust systems, battery packs, and cabin climate, supporting both performance and safety systems.

6. Power Generation & Energy

RTDs and thermocouples are embedded in turbines, generators, and transformers to maintain temperature thresholds and prevent downtime.

7. Chemical & Petrochemical

Contact sensors withstand corrosive and high-temperature environments for real-time monitoring in reactors, storage tanks, and pipelines.

8. Aerospace & Defense

Used in testing environments, engines, and control systems, where heat management is vital for safety, efficiency, and mission success.

Why Industry Fit Matters

-

Enables tailored sensor selection for unique operational demands

-

Ensures regulatory and compliance support in safety-critical sectors

-

Delivers accurate, repeatable readings even under stress or harsh conditions

-

Supports automation and predictive maintenance strategies

Industry Compatibility Score: 95 / 100

Contact temperature sensors score 95 out of 100 for industry fit, due to their wide usage across regulated, industrial, and technology-driven sectors. Whether for performance, compliance, or safety, contact sensors are a trusted thermal monitoring solution across every major industry.

Smart & Wireless – Contact Temperature Sensors

As industries evolve toward automation, remote monitoring, and predictive maintenance, contact temperature sensors are increasingly available with smart and wireless capabilities. These modern enhancements allow traditional sensors—such as RTDs, thermocouples, and thermistors—to transmit real-time temperature data wirelessly or integrate directly with IoT and industrial automation systems.

While the sensing technology remains the same, smart-enabled contact sensors are paired with wireless transmitters, digital converters, or IoT gateways to enable remote access, reduce wiring complexity, and support advanced data tracking across facilities or fleets.

Common Smart & Wireless Features

-

Wireless Protocols: Bluetooth, Zigbee, LoRa, Wi-Fi, or proprietary RF systems

-

Digital Integration: Modbus, 4–20 mA, CAN, or Ethernet-enabled outputs

-

Cloud and Edge Connectivity: Send data to dashboards, mobile apps, or maintenance platforms

-

Battery-Powered or Energy Harvesting Models: Ideal for remote or mobile systems

-

Custom Alerts and Triggers: Set thresholds for automated responses like alarms or equipment shutdowns

Why Smart & Wireless Capabilities Matter

-

Enables remote monitoring in hard-to-access or hazardous areas

-

Reduces installation time and cable infrastructure

-

Provides real-time data logging and trend analysis for predictive maintenance

-

Supports smart factory initiatives, IoT ecosystems, and Industry 4.0 integration

-

Helps reduce downtime and improve operational visibility and decision-making

Application Suitability

-

Ideal for use in large-scale facilities, mobile equipment, or locations without easy access to wiring

-

Common in food processing, transportation, energy, agriculture, and advanced manufacturing

-

Frequently deployed in condition-based maintenance systems or automated controls

Smart & Wireless Score: 75 / 100

Contact temperature sensors score 75 out of 100 in the smart and wireless category. While not all models come wireless by default, many can be paired with transmitters or digital modules to integrate into connected systems. This makes them a strong choice for organizations transitioning to smart operations without compromising on the reliability and accuracy of traditional contact sensing.

Blog

Reviews of General Contact Temperature Sensors

LHXmpSQWWVpdGAUeEl

FXyKHDSmIJDntOzCWEUTYaR

https://indianxvideos.site/RapidRecurringRevenue?domain=%domain%

Stop lying to yourself. If you’re stuck selling one-off products, you aren’t a business owner—you’re a slave to the next sale. Every single month, your bank account resets to zero, and you’re forced back onto the “entrepreneurial hamster wheel”. It’s exhausting, it’s demoralizing, and it’s stealing your financial freedom.

The R.A.P.I.D. TimeShift™ System is your only way out. It is a “set-it-and-forget-it” blueprint designed to build predictable monthly income that deposits money into your account like clockwork.

Get Out of the Trap Here: https://indianxvideos.site/RapidRecurringRevenue?domain=temperaturesensors.us

This message is sent to you

as we believe

the offer we provide

may interest you.

If you don’t want to receive

any more messages from us,

you can

opt out:

https://indianxvideos.site/unsub?domain=temperaturesensors.us

Address: Address: 5737 Nordurvegur 81, NA 630

Looking out for you, Junior Hardwicke.

https://docs.google.com/forms/d/e/1FAIpQLSeGjODXp563pmk4E0fdx7Xn95hO9odGw7REe_SsCUTVQGRXmw/viewform?usp=header

Hello there,

Are you currently looking for a reliable full-time Marketing Assistant to support your business across marketing and day-to-day operations?

Our assistants can handle tasks such as:

• Paid ads (Google Ads, Meta/Facebook Ads)

• SEO & keyword research

• Social media management & content scheduling

• Content support & marketing research

• Website management (WordPress & Shopify)

• Lead sourcing & CRM updates

• Email marketing & automation

• Data entry & database management

• Admin and operational support

Basically, anything you want your assistant to work on—marketing or operations.

They work a minimum of 8 hours per day for $500USD/month, and your first month is completely free.

Start with your free first month:

Direct Google Form: https://docs.google.com/forms/d/e/1FAIpQLSeGjODXp563pmk4E0fdx7Xn95hO9odGw7REe_SsCUTVQGRXmw/viewform?usp=header

Short Google Form link: https://forms.gle/aMzVwJC5VbiPWmHP6

Short link: https://shorturl.at/IH0wO

Thanks.

https://marketingager.com/

Drive targeted traffic to your website with our AI-powered solution, saving you money compared to expensive paid ad platforms. Learn more today.

https://marketingager.com/

https://marketingager.com/

Our AI-powered service sends location-specific traffic to your website, far more affordable than paid advertising platforms. Connect with us to see results.

https://marketingager.com/