General Bearing Sensor

Durable, fast-response temperature sensor for detecting heat buildup in bearings and rotating machinery, suitable for industrial and mobile equipment.

General Bearing Sensor

Durable, fast-response temperature sensor for detecting heat buildup in bearings and rotating machinery, suitable for industrial and mobile equipment.

General Bearing Sensor Insights

✅ Overall Score

Accuracy

Response Time

Temperature Range

Stability Over Time

Environmental Durability

Vibration Resistance

Chemical Resistance

Long-Distance Signal Accuracy

Compatibility with Data Systems

Contact vs. Non-Contact Measurement

Energy Efficiency / Power Needs

Cost-Effectiveness

Suitability for Extreme Cold

Suitability for Extreme Heat

Food & Medical Compliance

Overheat Protection & Safety

Automotive & Engine Performance

Industrial Process Control Suitability

HVAC & Climate Control

Ease of Installation & Maintenance

Temperature Sensor Overview:

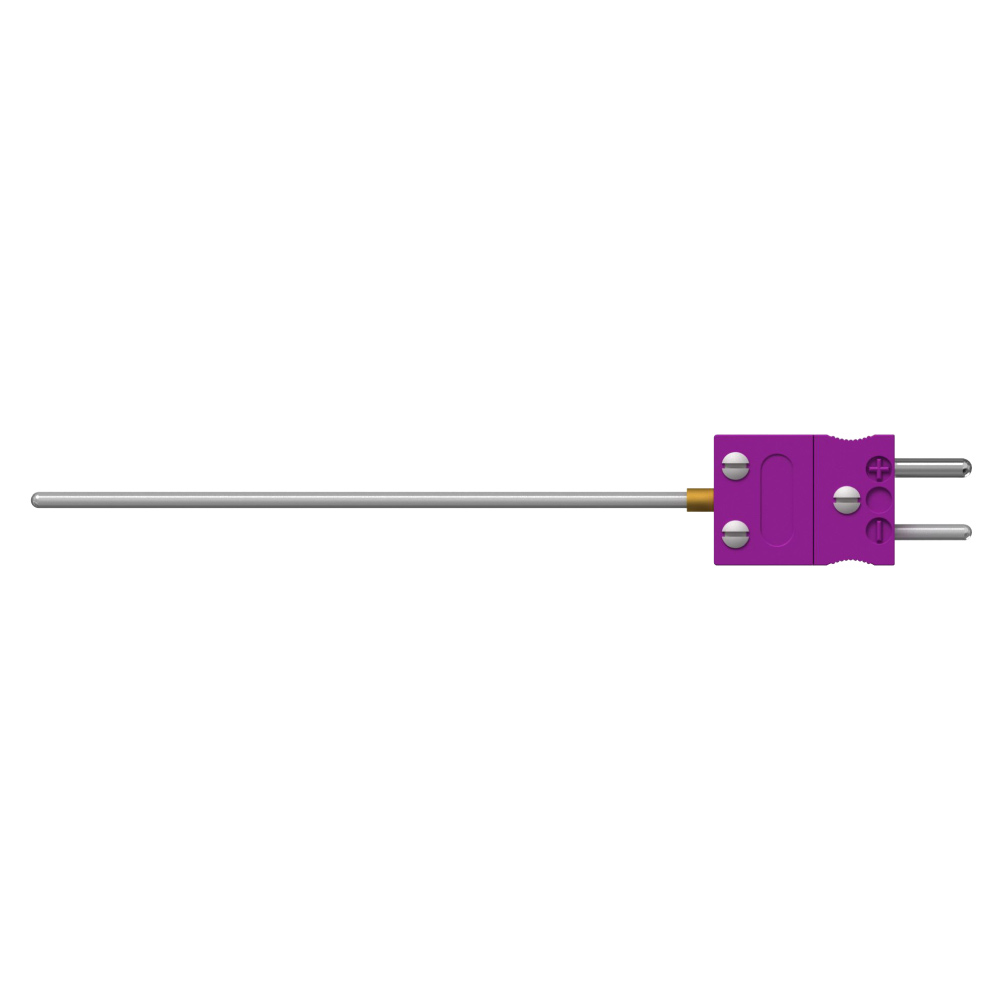

The General Purpose Bearing Temperature Sensor is engineered for reliable, real-time heat monitoring in bearings, gearboxes, motors, and rotating equipment. Built with rugged materials such as stainless steel or brass, this sensor offers fast response to temperature changes that signal wear or impending failure.

With optional RTD or thermocouple elements, it supports a wide range of temperatures and accuracy levels, and integrates easily with PLCs, maintenance systems, and safety alarms. Available in embedded or surface-mount formats, this sensor is ideal for use in manufacturing plants, mining operations, power stations, and agricultural equipment.

It ensures operators can detect early signs of friction or mechanical wear, helping prevent costly breakdowns and extend equipment life.

Temperature Sensor Specifications:

Temperature Sensor Type

-

RTD (PT100/PT1000)

-

Thermocouple (Type J, K, T)

Material Type

-

Stainless Steel

-

Brass

-

Optional: Ceramic tip, armored lead wires

Accuracy

-

±0.5°C to ±1.0°C

Industries

✔ Manufacturing & Industrial Automation

✔ Mining & Material Handling

✔ Automotive & Transportation

✔ Power Generation

✔ Food Processing (Sanitary Models)

✔ Agriculture & Equipment Monitoring

✔ Rail & Logistics

Accuracy Levels

Temperature Range

Typically operates between -50°C to 250°C, with high-temp variants (thermocouples) supporting up to 600°C, ideal for heavy-duty rotating machinery.

Response Time

Fast-response tip sensors or embedded probes allow quick detection of heat changes in bearings, minimizing failure risk.

Contact vs. Non-Contact Sensors

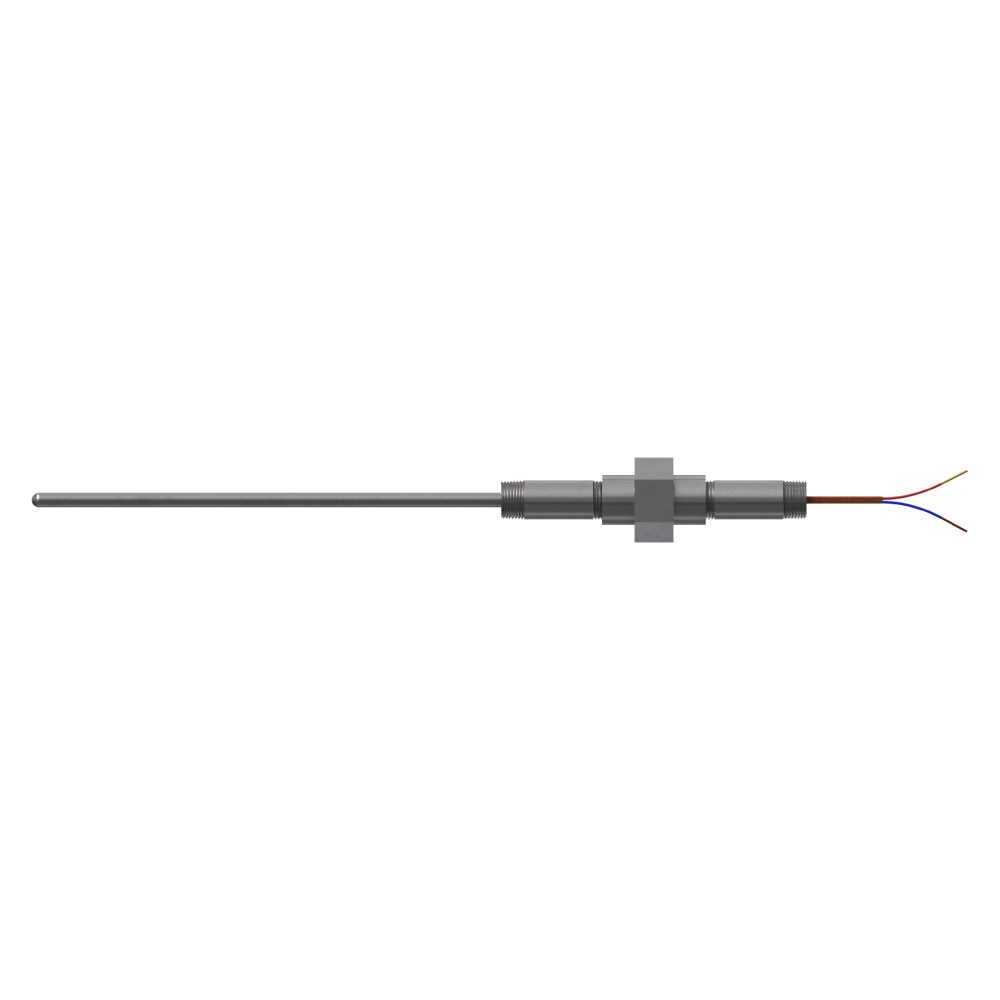

Bearing sensors are contact-based, either embedded or surface-mounted for direct thermal feedback from bearing housings or raceways.

Signal Stability

RTD-based bearing sensors are known for stable output over time, minimizing drift and false alarms in industrial conditions.

Power Requirements

RTDs and thermistors require external circuits, while thermocouples are self-powered, depending on the model used.

Environmental Durability

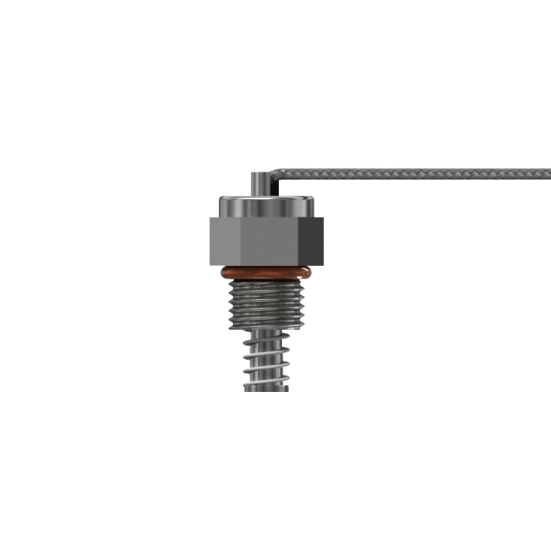

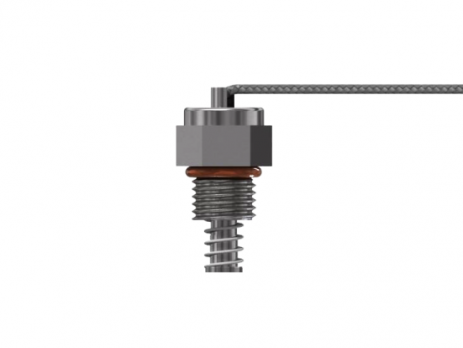

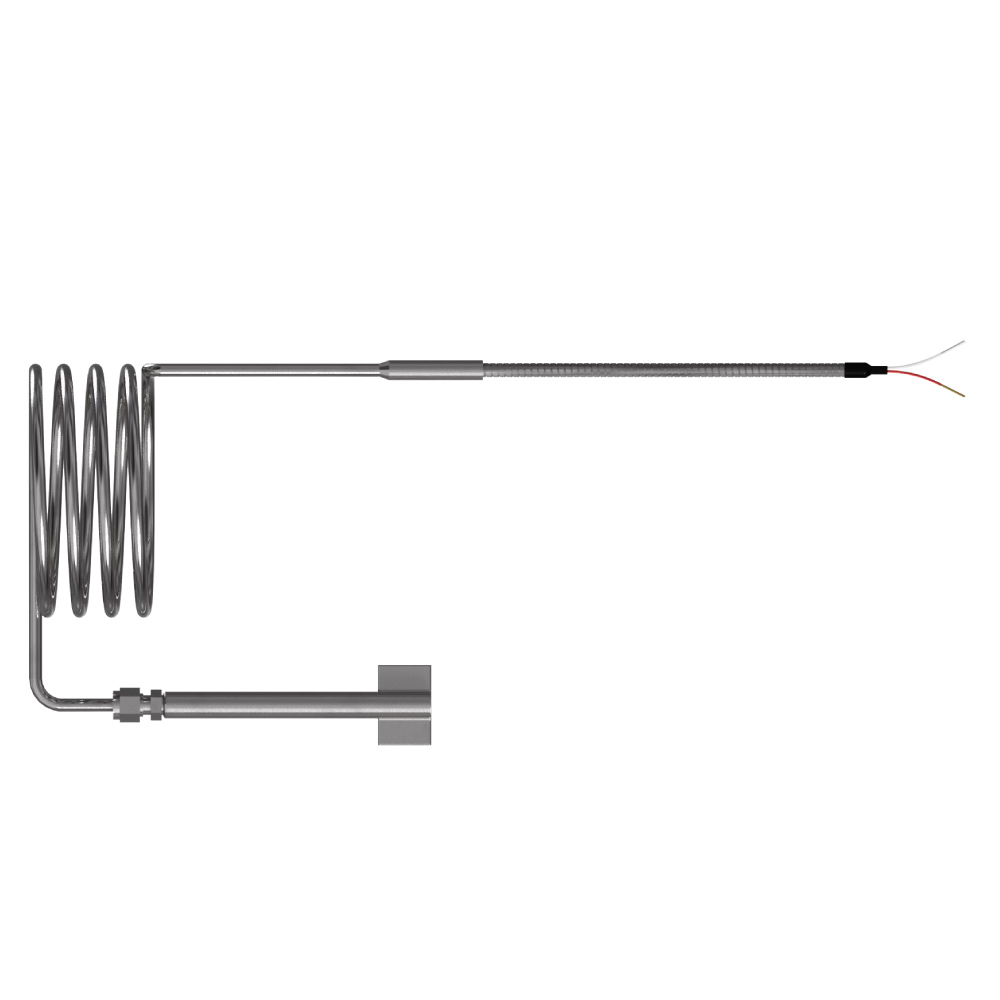

Constructed with sealed stainless steel or brass housings, bearing sensors are built to withstand oil, vibration, and debris in harsh environments.

Calibration & Maintenance

Routine calibration ensures accuracy in high-demand applications like conveyor systems and gearboxes, where overheating must be detected early.

Insulation & Sheathing

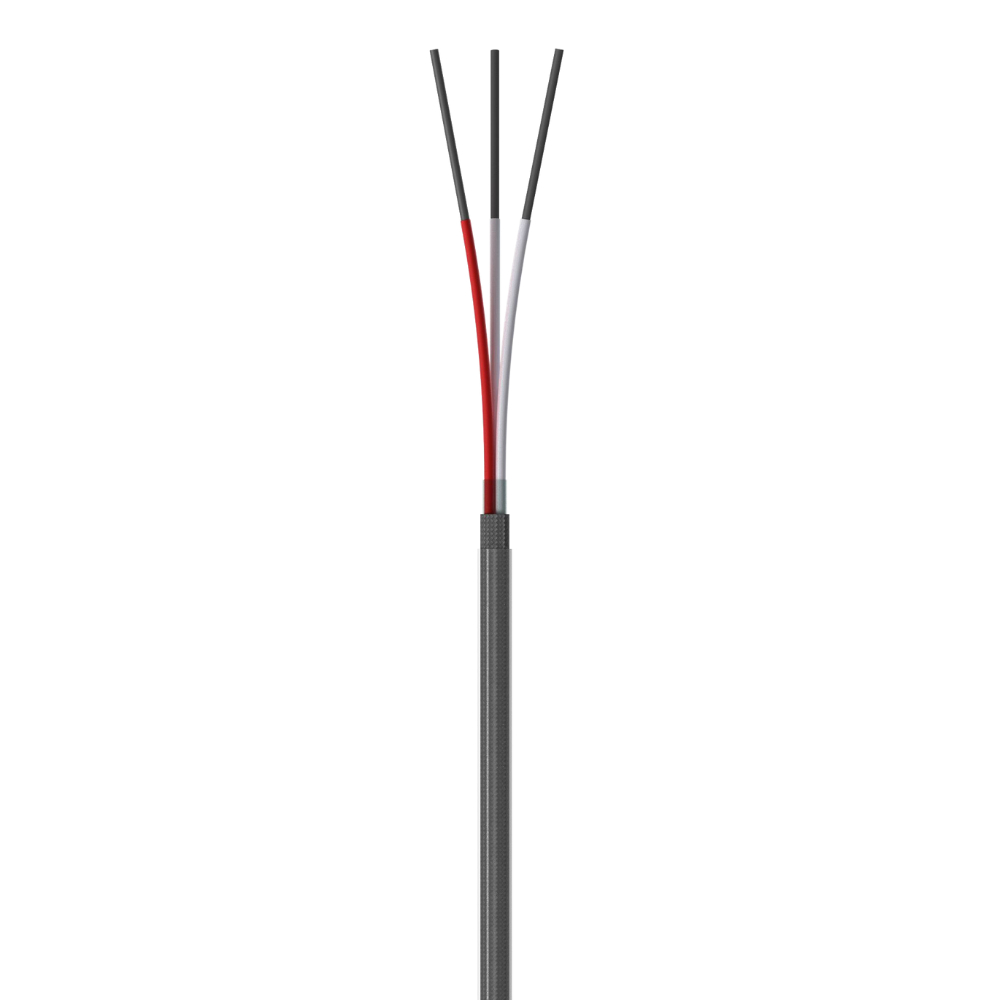

Protected with PTFE or braided insulation, often armored for long life in industrial machinery.

Sensor Placement & Installation

Designed for easy mounting into bearing housings, brackets, or threaded holes, proper placement ensures early heat detection.

Wire Length & Resistance Errors

Available with 2-, 3-, or 4-wire configurations; long wire runs benefit from 4-wire RTDs to avoid signal loss.

Overheat Protection

Often integrated with alarm or shutdown systems, these sensors trigger warnings when temperature thresholds are exceeded.

Waterproof & Humidity Resistance

IP65 to IP67 rated models are resistant to lubricants, water spray, and condensation, perfect for factory floors and outdoor use.

Wireless & IoT Integration

Some modern bearing sensors support wireless communication or can be connected to predictive maintenance dashboards via analog/digital signals.

Industry-Specific Sensors

Bearing sensors are used in mining, manufacturing, agriculture, power plants, and bulk material handling equipment.

Food & Medical Safety Compliance

Stainless steel variants with sanitary fittings are used in FDA-regulated food machinery and clean environments.

Extreme Cold Performance

Available in variants that support sub-zero temps, commonly used in cold storage and refrigerated conveyors.

Automotive & Transportation Sensors

Used in rail systems, heavy vehicles, and logistics hubs to detect “hot box” failures and prevent mechanical breakdowns.

Industrial Process Control

Critical in monitoring motor bearings, pumps, and rotating equipment for preventative maintenance and uptime assurance.

Protective Enclosures for Longevity

Available with sealed, armored, and explosion-proof housings to resist wear, impact, and contaminants over time.

Accuracy – Bearing Temperature Sensor

Accuracy plays a vital role in bearing temperature monitoring, where even small deviations in temperature can signal early signs of failure, excessive friction, or lubrication issues. General-purpose bearing sensors are typically built with RTDs (Resistance Temperature Detectors) or thermocouples, each offering reliable accuracy for industrial and mobile equipment applications.

Typical Accuracy Range

-

RTD-based sensors: ±0.5°C to ±1.0°C

-

Thermocouple-based sensors: ±1.0°C to ±2.0°C (depending on type, materials, and calibration method)

Why Accuracy Matters

Accurate bearing temperature monitoring is essential for:

-

Detecting early-stage wear or mechanical stress

-

Supporting predictive maintenance programs

-

Preventing unplanned downtime and equipment failure

-

Activating alarms or automated system shutdowns at critical thresholds

Application Suitability

-

RTD-bearing sensors are preferred in environments requiring precise, stable, long-term temperature tracking

-

Thermocouple-based sensors are often selected for applications needing broader temperature range or rugged durability

Accuracy Score: 80 / 100

This sensor earns an accuracy score of 80 out of 100, making it a strong performer for most industrial applications that demand dependable, repeatable temperature readings.

Response Time – Bearing Temperature Sensor

Response time refers to how quickly a sensor detects and reports changes in temperature. In bearing applications, a fast response time is critical for identifying overheating conditions before they lead to equipment damage or failure.

General-purpose bearing sensors are often tip-contact RTDs or thermocouples, embedded in or near the bearing housing. This close proximity allows for quick thermal transfer and rapid detection of any rise in temperature due to friction, misalignment, or lubrication breakdown.

Typical Response Time Range

-

Exposed-tip RTDs and thermocouples: 1 to 5 seconds

-

Sheathed or embedded sensors: 5 to 10 seconds (depending on material and installation depth)

Why Response Time Matters

A faster response time helps:

-

Detect bearing overheating before reaching critical levels

-

Improve safety by triggering alarms or shutdowns sooner

-

Enhance the accuracy of real-time monitoring systems

-

Reduce downtime by catching issues early in the failure cycle

Application Suitability

-

Surface-mount and embedded tip sensors offer the fastest response in dynamic, high-speed machinery

-

Sensors with ceramic or stainless steel sheathing may trade speed for durability but still offer reliable performance

Response Time Score: 85 / 100

This sensor earns a response time score of 85 out of 100, reflecting its ability to provide quick, reliable readings in rotating machinery, helping operators stay ahead of failures in real time.

Temperature Limits – Bearing Temperature Sensor

Temperature limits refer to the minimum and maximum temperatures a sensor can accurately and safely measure. In bearing applications, sensors must withstand both steady-state operating heat and potential thermal spikes caused by friction, overload, or mechanical failure.

General-purpose bearing sensors typically operate within a moderate to high temperature range, depending on whether they are built with RTDs or thermocouples. While most bearings do not experience extreme heat under normal conditions, sensors must be capable of withstanding sudden increases in temperature without degrading or losing accuracy.

Typical Operating Range

-

RTD-based bearing sensors: -50°C to 250°C

-

Thermocouple-based sensors: -50°C to 600°C (depending on type and sheath material)

Why Temperature Limits Matter

A wide and reliable temperature range ensures that the sensor can:

-

Function accurately during startup, peak load, and sustained operation

-

Detect abnormal rises in temperature before reaching failure thresholds

-

Perform consistently across varied environments, including cold storage or high-heat production lines

-

Avoid damage or loss of accuracy due to temperature-induced stress or sensor burnout

Application Suitability

-

RTDs are ideal for moderate heat environments with a focus on accuracy

-

Thermocouples are better suited for high-temperature applications or where the bearing may be subject to thermal surges

Temperature Range Score: 70 / 100

This sensor earns a temperature range score of 70 out of 100, offering sufficient range for most industrial and mobile bearing applications, while also supporting higher temperature needs when configured with thermocouples.

Contact vs. Non-Contact – Bearing Temperature Sensor

Bearing temperature sensors are contact-type sensors, meaning they must be physically in contact with the bearing surface or housing to measure temperature accurately. This direct-contact approach allows for real-time detection of heat buildup caused by friction, misalignment, or lack of lubrication within rotating equipment.

Unlike non-contact sensors (such as infrared or thermal imaging devices), which detect surface temperature from a distance, contact sensors provide more accurate, localized temperature readings in closed or enclosed mechanical systems like motors, gearboxes, and conveyors.

Why Contact Measurement Matters for Bearings

-

Ensures precise tracking of internal bearing temperatures

-

Provides continuous readings in sealed or lubricated housings

-

Allows integration into safety and shutdown systems

-

Works in environments where infrared sensors would be blocked by housing, oil, or debris

Limitations of Non-Contact for Bearings

-

Non-contact sensors cannot see through housing or insulation

-

More susceptible to environmental interference (e.g., dust, steam, oil film)

-

Typically not used for internal or embedded sensing in bearings

Application Suitability

-

Surface-mount and embedded contact sensors are ideal for bearings and rotating assemblies

-

Non-contact sensors are better suited for open systems, moving targets, or hazard zones, but not for bearing internals

Contact vs. Non-Contact Score: 60 / 100

This bearing sensor earns a score of 60 out of 100 in this category, as it is highly optimized for contact measurement but not designed for non-contact use. It excels in precision and reliability where direct thermal sensing is required but is not suited for applications needing remote temperature detection.

Durability – Bearing Temperature Sensor

Durability is one of the most critical attributes of a bearing temperature sensor, especially in industrial environments where vibration, dust, oil, heat, and mechanical stress are constant. These sensors are often installed in or near rotating equipment and must maintain performance over long periods, even under harsh operating conditions.

General-purpose bearing sensors are typically constructed with stainless steel or brass housings, and often include sealed, vibration-resistant designs. Some models also feature armor-braided cables, PTFE insulation, or epoxy potting to protect internal components and ensure long-term reliability.

Key Durability Features

-

Ingress protection (IP65–IP67) for resistance to dust, moisture, and splashes

-

Vibration-resistant construction for motors, gearboxes, and heavy machinery

-

Corrosion-resistant materials to withstand exposure to oil, grease, and cleaning chemicals

-

Reinforced cables and terminals for protection against movement, tension, and fatigue

Why Durability Matters

-

Ensures reliable long-term operation without frequent sensor replacement

-

Reduces downtime and maintenance costs due to sensor failure

-

Maintains performance in uncontrolled or outdoor environments

-

Protects internal components from mechanical shock, vibration, or contamination

Application Suitability

-

Ideal for use in manufacturing, mining, transportation, and heavy-duty equipment

-

Suitable for environments where grease, oil, dust, and high vibration are present

-

Available in configurations for mobile machinery, power generation, and process industries

Durability Score: 90 / 100

This sensor earns a durability score of 90 out of 100, making it a reliable choice for demanding industrial applications. Its rugged construction and protective design ensure consistent performance over extended operating cycles, even in harsh conditions.

Long-Term Accuracy – Bearing Temperature Sensor

Long-term accuracy refers to a sensor’s ability to maintain consistent, reliable measurements over extended periods of use, without significant drift or degradation. In bearing applications, where sensors often operate continuously in high-vibration, high-load environments, maintaining accuracy over time is essential for preventing unexpected failures and supporting predictive maintenance systems.

General-purpose bearing sensors, especially those built with RTD (Resistance Temperature Detector) elements, are known for their excellent long-term stability. These sensors deliver reliable performance even after thousands of operating hours, provided they are installed correctly and used within their specified temperature and environmental limits.

What Impacts Long-Term Accuracy

-

Sensor element type (RTDs offer superior long-term stability compared to thermocouples)

-

Environmental exposure (dust, vibration, moisture, and chemicals can impact sensor performance if not properly protected)

-

Material quality and insulation (high-grade materials extend lifespan and minimize drift)

-

Frequency of calibration (routine calibration helps preserve precision over years of use)

Why Long-Term Accuracy Matters

-

Ensures dependable data for maintenance scheduling and alerts

-

Reduces the need for frequent recalibration or early sensor replacement

-

Supports consistent safety thresholds and shutdown triggers

-

Maintains trust in sensor data for automated systems and human operators alike

Application Suitability

-

Well-suited for permanently installed systems in motors, pumps, conveyors, and gearboxes

-

Commonly used in high-uptime environments such as power plants, factories, and processing facilities

-

Ideal for systems requiring low-drift, low-maintenance sensors

Long-Term Accuracy Score: 85 / 100

This bearing temperature sensor earns a score of 85 out of 100 for long-term accuracy, reflecting its strong performance in continuous-use industrial settings. It provides stable, consistent data over time, especially when configured with RTD elements and installed with proper insulation and environmental protection.

Key Industries – Bearing Temperature Sensor

Bearing temperature sensors are used across a wide range of industries where rotating machinery, motors, conveyors, and gearboxes are critical to operations. These sensors help detect early signs of friction, misalignment, or lubrication failure, making them essential for predictive maintenance and equipment protection in demanding environments.

Their rugged design, reliable accuracy, and fast response time make them suitable for industrial, transportation, and energy sectors, among others.

Most Common Industries That Use Bearing Sensors

1. Manufacturing & Industrial Automation

Used in motors, fans, gearboxes, and conveyor systems to detect bearing overheating before it leads to production downtime.

2. Mining & Material Handling

Helps monitor heavy-duty equipment such as crushers, conveyors, and loaders, where bearing failure could halt entire operations.

3. Power Generation

Monitors generator bearings, turbine shafts, and other rotating components to ensure continuous performance and prevent costly breakdowns.

4. Automotive & Transportation

Installed in rail systems and industrial vehicles to detect overheating in wheel hubs and drivetrains—critical for safety and performance.

5. Food & Beverage Processing

Sanitary-grade sensors monitor bearings in food-safe machinery, helping meet FDA and HACCP compliance standards.

6. Agriculture & Equipment Monitoring

Used in harvesters, conveyors, and automated systems for early warning of bearing stress in rugged, outdoor environments.

7. Steel Mills & Heavy Industry

Monitors high-load, high-temperature bearings in rollers, presses, and continuous production lines where downtime is extremely costly.

Why It Matters

-

Improves equipment uptime by detecting failures early

-

Reduces maintenance costs through data-driven scheduling

-

Increases safety in high-risk operations like mining, rail, and energy

-

Supports compliance in regulated industries like food, pharma, and medical

Industry Fit Score: 95 / 100

This bearing temperature sensor scores 95 out of 100 in industry compatibility due to its wide applicability, rugged design, and proven performance in critical equipment across multiple sectors. It’s a trusted solution in both standard industrial environments and highly specialized operations.

Smart & Wireless – Bearing Temperature Sensor

Modern bearing temperature sensors are increasingly integrating with smart systems and wireless technologies to enable real-time monitoring, remote diagnostics, and predictive maintenance. While many traditional bearing sensors are analog and hardwired, newer models offer digital outputs, wireless transmission, and IoT compatibility, enhancing their value in data-driven industrial environments.

These smart-enabled sensors can transmit data to central control systems, cloud platforms, or mobile apps, helping maintenance teams monitor bearing health without needing to be physically near the equipment.

Common Smart & Wireless Features

-

Wireless Protocols: Bluetooth, Zigbee, LoRa, and Wi-Fi for remote connectivity

-

Digital Output Options: Modbus, CAN, 4–20 mA with transmitters

-

Battery-Powered or Energy-Harvesting Models for untethered operation

-

Integration with Predictive Maintenance Systems for real-time analytics

-

Alerts and Threshold-Based Triggers via mobile or dashboard notifications

Why Smart & Wireless Capabilities Matter

-

Enables remote monitoring in hard-to-access or hazardous areas

-

Reduces the need for manual checks or wiring infrastructure

-

Provides real-time alerts for overheating or failure trends

-

Supports scalable, automated maintenance programs

-

Enhances equipment visibility in Industry 4.0 and smart factory systems

Application Suitability

-

Ideal for large industrial facilities, remote equipment, and rotating systems in motion

-

Useful in agriculture, mining, manufacturing, and power generation where wireless access improves safety and efficiency

-

Can be retrofitted or configured for condition-based monitoring programs

Smart & Wireless Score: 75 / 100

This general-purpose bearing sensor scores 75 out of 100 in the smart and wireless category. While not all models include wireless by default, many can be upgraded with transmitters or purchased in wireless-ready configurations, making it a strong performer for organizations looking to modernize their maintenance strategy.

Blog

Reviews of General Bearing Sensors

https://jvz4.com/c/688203/433889/

Most people don’t fail online because they lack opportunity.

They fail because the thinking overwhelms them.

What should I build?

How do I structure it?

What comes next?

That mental weight is what kills momentum.

ClawMate was built to remove that layer completely.

It’s not another chatbot waiting for prompts.

Click here for more : https://jvz4.com/c/688203/433889/

https://www.youtube.com/watch?v=ss4tux6Q4pI

Stop wasting months on content creation and start selling a professional, ready-to-use video course that positions you as an instant authority in the digital business space. This complete white-label package allows you to grow your email list and generate recurring income without spending a single minute on planning, scripting, or recording https://www.youtube.com/watch?v=ss4tux6Q4pI

https://www.youtube.com/watch?v=3013L2Yxg1k

Stop losing money on visitors who leave websites and start automatically redirecting that “wasted” traffic toward your own offers for as little as five cents per person. Exit Traffic Network provides a completely hands-free, set-it-and-forget-it system that captures real desktop traffic from established platforms while you sleep

https://www.youtube.com/watch?v=3013L2Yxg1k

https://www.youtube.com/shorts/A-OuNefvXeA

Discover how our AI can skyrocket your Temperaturesensors Us website leads in this quick video: https://www.youtube.com/shorts/A-OuNefvXeA

https://www.youtube.com/watch?v=ksq5cZApb3E

Skip months of hard work and launch a high-converting AI business today using this professionally designed “Business In A Box”. With full Private Label Rights, you can rebrand these expert assets as your own and keep 100% of the profits from every sale.